For several decades, conveyor pulley bearing housings were protected from the environment with labyrinth type sealing methods. While there have been iterations over the years, they fundamentally adopt a ‘grease filled torturous path’ approach to sealing.

DASH Engineering are impartial and independent bearing consultants located in Perth, Western Australia, specializing in failure analysis of rolling element bearings. Having conducted hundreds of conveyor pulley failure investigations, with the majority of failures attributed to contamination ingress, DASH Engineering have proven that traditional sealing methods and the industry standard – ‘Three Barrier Solution’ – are not effective in preventing dirt and water ingress into the bearing housing. Independent testing and numerous case studies have demonstrated that grease acts as a carrier for contamination rather than a barrier. Additionally, traditional sealing methods do not accommodate the misalignment and float that is required in conveyor pulley applications.

…” this is a step change in Mining” – Manager-Asset Management

Premature bearing failure from contamination ingress

Premature bearing failure from contamination ingress

With the overwhelming majority of DASH Engineering failure reports recommending to ‘review sealing methods’, it became evident that there was no other effective method of keeping contamination out of the bearing housing, sparking the development of the SAPO® Seal.

…” savings will be comparable to AutoHaul” – Site-based Project Manager

The Self-Aligning Pressurised Oil (SAPO®) Seal is a patented, engineered sealing solution that will accommodate misalignment requirements without compromising on sealing effectiveness. Furthermore, SAPO® Seals are fully maintainable, monitorable and predictable providing peace of mind to the end user.

SAPO® Seal

SAPO® Seal

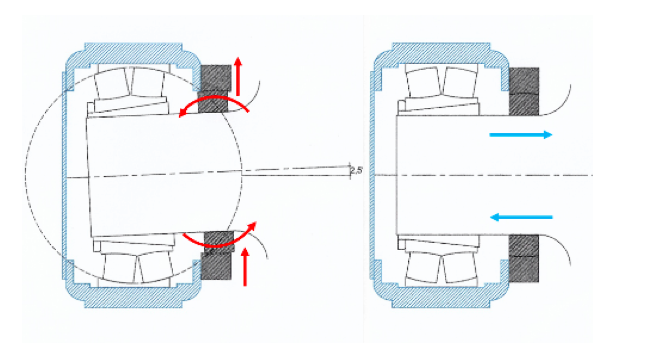

In order to effectively maintain positive sealing, the SAPO® Seal is designed to float with respect to the housing as well as remain parallel with the shaft. This unique design allows for articulation to the allowable misalignment limits of spherical roller bearings.

SAPO® Seal articulation and axial float

SAPO® Seal articulation and axial float

The SAPO® Seal does not rely on grease as a sealing medium. Positive pressure oil is used to ensure the oil seal lips remain lubricated and simultaneously captures fine dust particles. Regular oil sampling and flushing ensures seal performance is monitored and maintained throughout its life.

…” we need to make them all like this” – Fitter-Site Installation Team

Current plummer block sealing methods tend to damage shafts – often damaged beyond repair. SAPO® Seals eliminate this problem with a simple solution. The units are designed to run on wear sleeves to prevent abrasive damage to shafts.

Before SAPO® Seals

Before SAPO® Seals After SAPO® Seals

After SAPO® Seals

SAPO® Seals are fully maintainable, monitorable and predictable with state-of-the-art intra-bearing housing endoscopic monitoring via the SAPO® Scope. Maintenance personnel are able to visually monitor the housing cavity for contamination ingress and excessive bearing greasing whilst the machine is fully operational. This type of visual monitoring is truly unique in providing peace of mind and removes any doubt in regard to contamination ingress.

Bearing housing endoscopic monitoring with the SAPO® Scope

Bearing housing endoscopic monitoring with the SAPO® Scope

SAPO® Seals can also be used to assist with pulley alignment during installation, reducing set-up time and risk, increasing safety and efficiency. A simple yet effective technique allows for on-the-go visual alignment guidance and final quality assurance checks to remove any doubt during pulley install.

…” most significant benefit will be that we finally have effective, multi-level monitoring of bearing condition as risk mitigation against unplanned failures” – Site Engineer

The implementation of SAPO® Seals have enabled multiple critical pulleys to achieve upwards of two times the previous mean time between failure (MTBF) across Australia’s Pilbara iron ore operations. Case studies on high grade iron ore conveyor systems have resulted in:

Installation of critical pulley with SAPO® Seals

Installation of critical pulley with SAPO® Seals

SAPO® Seals allow clients to switch from time-based maintenance techniques to condition-based maintenance methods.

A large 2m diameter pulley weighing approximately 28 tonnes on a system conveying bulk material across the Pilbara was changed out every six months due to repeated rapid

SAPO® Seal in operation

SAPO® Seal in operation

contamination ingress related failures. The site team decided to make the switch to SAPO® Seals and have experienced reliability and predictability to another level.

Another critical pulley on a ship loader conveyor system was experiencing reliability issues that caused unplanned downtime costing hundreds of thousands of dollars. The pulley was fitted with SAPO® Seals at the next opportunity and has been operating reliably since the switch.

The implementation of SAPO® Seals required no modifications to standard ‘SD’ type bearing housings.